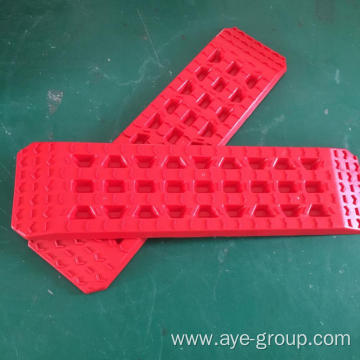

Plastic Recovery Tracks, Recovery Traction Tracks,Sand Tracks,4WD off-Road Traction Board, Sand/Snow Ladder

Outback Australia is a place which is very inhospitable. If you didn`t prepared well for recovering your vehicle from sand, snow or mud among your trip, you might be crazy that your vehicle was in for a long night.So it is necessary to prepare a well Recovery Traction Board for your trip.

History of Sand Ladder

Without any doubt, people have been making sand recovery tracks since the development of the first motor vehicle and sand ladders are definitely not a new invention. However, the first commercially available sand ladder was invented by the U.S. Army and commenced manufacture in 1941 called Marsden Matting. It was extremely functional and was primarily used for the fast temporary construction of air fields and vehicle tracks on soft and muddy ground. An estimated 800 million square feet of Marsden Matting was manufactured during World War II.

Later Marsden Matting became known as PSP (perforated steel planking) and was constructed from a magnesium steel alloy. It was also manufactured from aluminium and called PAP which weighed significantly less than it's steel counterpart. This military surplus PAP became the first sand ladders to be commonly used by 4wd enthusiasts and was popular on the roof racks of Land Rovers.

World War II Sand Ladder

Steel and aluminium Sand Ladders were used in WWII to build temporary air fields and roads. It was called Marsden Matting or later PSP or PAP. It was a quick solution to allow vehicles through soft and muddy ground.

4wd vehicle owners often still make use of these types of sand ladders and offer a military look on the outside of some Land Rovers.

Definitions:

Sand Ladders

A Sand Ladder is any rigid formation of steel, aluminium or plastic device that provides some strength for use in bridging and ramping also.

Sand Mats

A Sand Mat is a soft carpet-like device that is flexible and includes a variety of rubber matting and rolling segments.

Bridging Ladders

Often Bridging Ladders are far more bulky and maintain a lot more strength when used in bridging or ramping configurations and their size should be considered when purchasing.

Plastic Sand Ladders

Moulded in high visibility Reinforced Engineering Plastic, they stand out as a light weight, easy to handle alternative to the aluminium and steel counterparts. With moulded lugs for grip on the top and underneath, they work brilliantly for easy sand ,snow and mud recovery.

Advantage:

· Best performance in snow,mud ,sand and wet conditions

· Light weight, at 4.00kgs for the pair

· No sharp edges

· Easy to carry